As an industrial site owner, ensuring the safety of your staff and visitors is of utmost importance. In addition to ensuring compliance with relevant legislation and standards, such as the Workplace Health and Safety (WHS) Act, conducting a site safety audit can help identify potential hazards and risks, and implement mitigation measures to minimise the risks.

What is a Site Safety Audit?

A site safety audit involves a comprehensive assessment of a site’s safety risks, including traffic flow, pedestrian safety, parking layout compliance, and Disability Discrimination Act (DDA) compliance, among others. Site audits are conducted by RPEQ certified traffic engineers, who use their expertise and experience to identify all potential issues and hazards.

The Guide to Traffic Impact Assessments (GTIA) provides guidance on conducting site safety audits. The GTIA is a document that provides a standardised approach to assessing the traffic impact of new developments or changes to existing developments and includes guidance on conducting site safety audits.

The Process of Conducting a Site Safety Audit

The process of conducting a site safety audit typically involves the following steps:

Risk Identification – RPEQ certified traffic engineers conduct a site visit and use their expertise to identify all potential issues and hazards, such as inadequate signage, poor visibility, inefficient parking layout, lack of speed control and unsafe pedestrian networks.

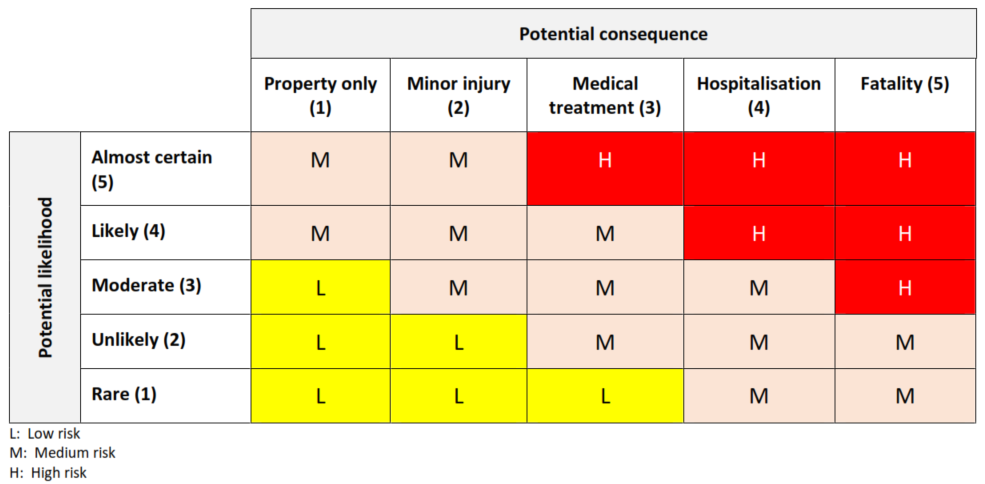

Risk Assessment – Risks identified during the audit are assessed in accordance with the risk matrix set out in the GTIA to determine the level of risk. The risk matrix takes into account the likelihood of the risk occurring and the consequences if it does occur. A copy of the risk matrix is shown below.

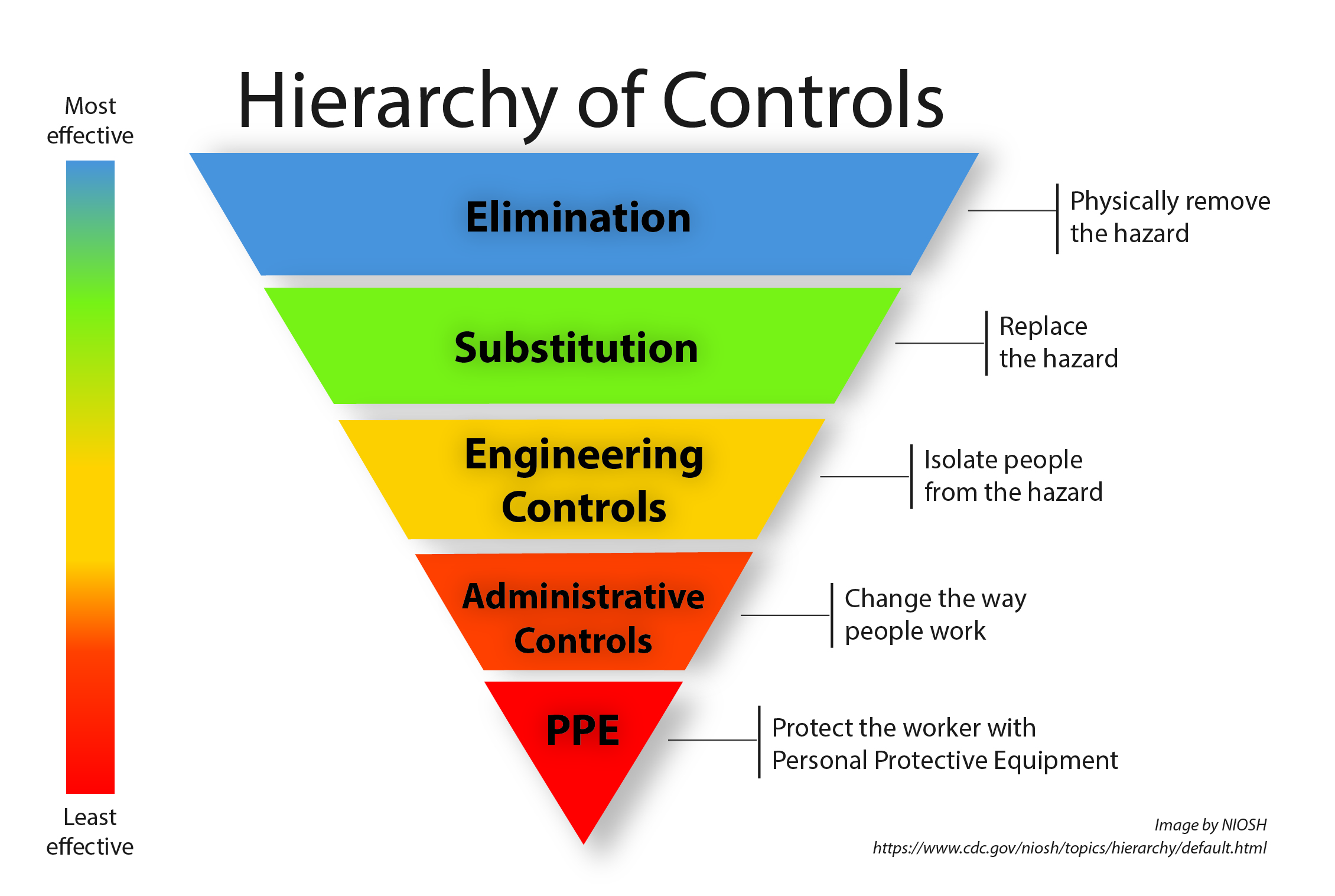

Mitigation Measures – Mitigation measures are then devised to minimise the risks. The control hierarchy is used which involves identifying and implementing the most effective control measures, starting with eliminating the hazard, and moving through substitution, engineering controls, administrative controls, and personal protective equipment (PPE). The control hierarchy is shown below.

Implementation – The identified mitigation measures are then implemented, with ongoing monitoring and review to ensure they remain effective.

The Importance of Compliance with Relevant Legislation and Standards

In addition to complying with the WHS Act, industrial sites must comply with other relevant legislation and standards, such as the Manual of Uniform Traffic Control Devices (MUTCD) and Australian Standards. Compliance with these standards ensures that the site is safe for all users, including staff, visitors, and the local community.

The Importance of Involving Stakeholders in the Audit Process

To ensure a comprehensive assessment of the site’s safety risks, it is important to involve stakeholders in the audit process. This includes employees, customers, and the local community, who may have valuable insights into potential hazards or risks. Involving stakeholders also helps to build trust and transparency and demonstrates a commitment to safety and compliance.

Benefits of Conducting a Site Safety Audit

There are several benefits to conducting a site safety audit, including:

Improved Reputation – Conducting a site safety audit demonstrates a commitment to safety and compliance, which can improve the reputation of the business.

Increased Efficiency – Identifying inefficiencies in operations and processes during a site safety audit can lead to cost savings and increased productivity. For example, a more efficient parking layout could lead to more parking spaces or more capacity for business operations, such as truck loading capacity.

Sustainability Improvements – A site safety audit can identify opportunities for sustainability and environmental improvements, such as reducing carbon emissions and waste.

Avoidance of Lawsuits – Addressing site problems identified in an audit could help to avoid lawsuits from staff or customers who may be injured on the site.

Conclusion

Conducting a site safety audit by an RPEQ certified traffic engineer is essential for ensuring the safety of staff and visitors at industrial sites. It not only helps identify potential hazards and risks but also provides a range of benefits, including improved reputation, increased efficiency, and avoidance of lawsuits.

The team at Velocity Traffic Engineering specialises in conducting site safety audits and can help you achieve these benefits. Contact us today to schedule a consultation and take the first step towards protecting your site and improving its safety.